1. Kuongorora chimiro

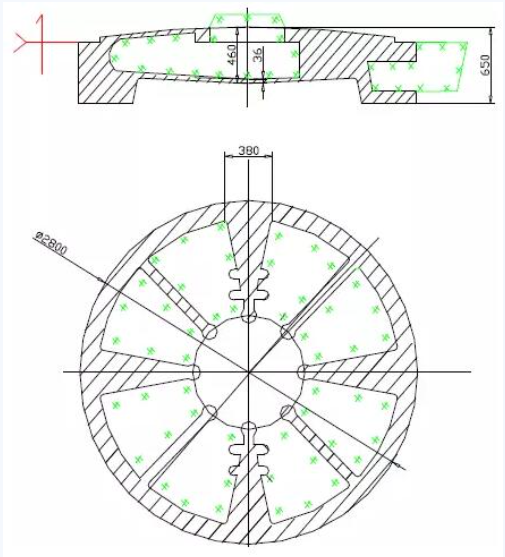

(1) Izvivharuvhu yeshavishaviine chimiro chedenderedzwa chakaita sekeke, gomba remukati rakabatana uye rinotsigirwa nembabvu 8 dzinosimbisa, gomba repamusoro reΦ620 rinotaurirana negomba remukati, uye zvimwe zvese zvevharuvhuyakavharwa, mukati mejecha zvakaoma kugadzirisa uye zviri nyore kukanganisika. Kubuda kwemhepo nekucheneswa kwemukati megomba zvinounza matambudziko makuru, sezvakaratidzwa paMufananidzo 1.

Ukobvu hwemadziro emakasino hunosiyana zvikuru, ukobvu hwemadziro hwakanyanya hunosvika 380mm, uye ukobvu hwemadziro hushoma hunosvika 36mm chete. Kana kasino yaoma, musiyano wekupisa unenge wakakura, uye kudonha kusina kuenzana kunogona kubudisa nyore nyore makomba ekupwanya uye kushaya maburi, izvo zvinozoita kuti mvura ibude mu hydraulic test.

2. Kugadzira maitiro:

(1) Nzvimbo yekuparadzanisa inoratidzwa muMufananidzo 1. Isa mugumo une maburi pabhokisi repamusoro, gadzira dumbu rese rejecha pakati pegomba, uye wedzera musoro wepakati zvakakodzera kuti zvive nyore kusungirira dumbu rejecha uye kufamba kwedumbu rejecha kana bhokisi ratenderedzwa. Rakagadzikana, kureba kwemusoro wepakati we cantilever wemaburi maviri asingaonekwe padivi kwakareba kupfuura kureba kwegomba, kuitira kuti pakati pesimba rejecha rese padivi pave nechekudivi kwemusoro wejecha kuti uve nechokwadi chekuti dumbu rejecha rakagadzikana uye rakagadzikana.

Sisitimu yekudira yakavharwa zvishoma inotorwa, ∑F mukati: ∑F yakatwasuka: ∑F yakatwasuka=1:1.5:1.3, sprue inoshandisa chubhu yeceramic ine dhayamita yemukati yeΦ120, uye zvidimbu zviviri zvezvidhinha zvinoramba zve200×100×40mm zvinoiswa pasi kudzivirira simbi yakanyungudutswa kubva zvakananga. Kune impact sand mold, 150×150×40 foam ceramic filter inoiswa pasi pe runner, uye machubhu eceramic gumi nemaviri ane dhayamita yemukati yeΦ30 anoshandiswa kuti runner yemukati ibatanidzwe zvakaenzana pasi pe casting kuburikidza netangi rekuunganidza mvura pasi pe filter kuti igadzire plani yekudira pasi, sezvakaratidzwa muMufananidzo 2 Essence

(3) Isa maburi emhepo ane 14 ∮20 muchimiro chepamusoro, isa gomba remhepo rine Φ200 jecha pakati pemusoro wepakati, isa simbi inotonhora muzvikamu zvakakura uye zvakakora kuti uve nechokwadi chekuti casting inosimba zvakaenzana, uye shandisa graphitization expansion principle kuti udzime. Feeding riser inoshandiswa kuvandudza goho remaitiro. Saizi yebhokisi rejecha i3600×3600×1000/600mm, uye inosungirirwa nesimbi ine 25mm gobvu kuti ive nechokwadi chekuti yakasimba uye yakasimba, sezvakaratidzwa muMufananidzo 3.

3. Kudzora maitiro

(1) Kugadzira Modhi: Usati wagadzira modhi, shandisa sampuro yakajairika yeΦ50×50mm kuti uedze simba rekudzvanya rejecha re resin ≥ 3.5MPa, uye simbisa simbi inotonhora nerunner kuti uve nechokwadi chekuti furu yejecha ine simba rakakwana rekugadzirisa graphite inogadzirwa kana simbi yakanyungudutswa yaoma. Kukura kwemakemikari, uye kudzivirira simbi yakanyungudutswa kuti isarove chikamu cherunner kwenguva yakareba zvichikonzera kusukwa kwejecha.

Kugadzira core: core yejecha yakakamurwa kuita zvikamu zvisere zvakaenzana nembabvu sere dzinosimbisa, dzakabatana nepakati pegomba. Hapana zvimwe zvikamu zvinotsigira uye zvinoburitsa kunze kwemusoro wepakati. Kana core yejecha isingagone kugadziriswa uye Exhaust, kutama kwecore yejecha uye maburi emhepo zvichaonekwa mushure mekudurura. Nekuti nzvimbo yese yecore yejecha yakakura, yakakamurwa kuita zvikamu zvisere. Inofanira kunge iine simba rakakwana uye kuomarara kuti ive nechokwadi chekuti core yejecha haizokuvadzwi mushure mekubuda kwemold, uye haizokuvadzwi mushure mekudurura. Kuchinja kunoitika, kuitira kuti madziro esimbi akaenzana. Nechikonzero ichi, takagadzira core bone chaiyo, ndokuisunga pabhonzo repakati netambo yekufema kuti tibvise exhaust gasi kubva mumusoro wepakati kuti tive nechokwadi chekuti mold yejecha yakamanikana pakugadzira core. Sezvakaratidzwa muMufananidzo 4.

(4) Bhokisi rekuvhara: Tichifunga kuti zvakaoma kuchenesa jecha riri mukati mevharuvhu yemapuruguru, mukati mejecha rese rinopendwa nependi mbiri, chikamu chekutanga chinokweshwa nependi yezirconium ine alcohol (Baume degree 45-55), uye chikamu chekutanga chinopendwa nekupiswa. Mushure mekuomesa, penda chikamu chechipiri nependi yemagnesium ine alcohol (Baume degree 35-45) kudzivirira kuti kukanda kusanamatira mujecha uye kusviba, izvo zvisingagone kucheneswa. Chikamu chemusoro wepakati chinoturikwa papombi yesimbi yeΦ200 yechimiro chikuru chebhonzo repakati ne screws nhatu dzeM25, dzakasungirirwa uye dzakakiyiwa nebhokisi rejecha repamusoro rine screw caps uye dzinoongorora kana ukobvu hwemadziro echikamu chimwe nechimwe hwakafanana.

4. Maitiro ekunyungudutsa nekudurura

(1) Shandisa simbi yenguruve yeBenxi low-P, S, Ti yepamusoro-soro Q14/16#, woiisa pachiyero che40%~60%; zvinhu zvidiki zvakaita seP, S, Ti, Cr, Pb, nezvimwewo zvinodzorwa zvakasimba musimbi dzakasara, uye hapana ngura nemafuta zvinobvumidzwa, chiyero chekuwedzera i25%~40%; muripo unodzoserwa unofanirwa kucheneswa nekuputika kwepfuti usati washandisa kuti uve nechokwadi chekuchena kwemuripo.

(2) Kudzora kukuru kwechikamu mushure mechoto: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (yasara): 0.035% ~0.05%, pasi pepfungwa yekuona kuti spheroidization, muganho wakaderera weMg (yasara) unofanirwa kutorwa zvakanyanya sezvinobvira.

(3) Kurapa kweSpheroidization: maspheroidizers ane magnesium shoma uye spheroidizers asina kuwanda anoshandiswa, uye chiyero chekuwedzera i1.0% ~ 1.2%. Kurapa kweSpheroidization nenzira yemazuva ese, 0.15% yekubaiwa kamwe chete inofukidzwa pa nodulizer iri pasi pepakeji, uye spheroidization inopedzwa. Slag inozobva yabviswa kuti ibaiwane yechipiri ye0.35%, uye kubaiwa kwemvura ye0.15% kunoitiswa panguva yekudurura.

(5) Maitiro ekudurura nekukurumidza kushoma anoshandiswa, tembiricha yekudurura iri 1320°C~1340°C, uye nguva yekudurura iri 70~80s. Simbi yakanyungudutswa haigone kukanganiswa panguva yekudurura, uye kapu yesprue inogara yakazara kudzivirira gasi nezvimwe zvinosanganisirwa kuti zvisapinde mumold kuburikidza nepaburi.

5. Mhedzisiro yebvunzo yekukanda

(1) Edza simba rekudhonza rebhokisi rekuyera rakakandwa: 485MPa, kureba: 15%, kuomarara kweBrinell HB187.

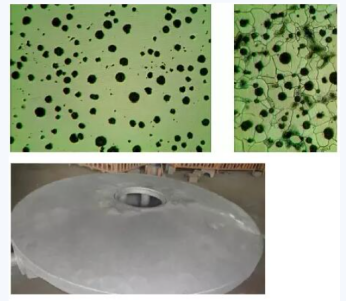

(2) Mwero we spheroidization i95%, saizi ye graphite igiredhi 6, uye pearlite i35%. Chimiro che metallographic chinoratidzwa muMufananidzo 5.

(3) Hapana zvikanganiso zvinorekodhwa zvakawanikwa pakuona zvikanganiso zve UT neMT zvezvikamu zvakakosha.

(4) Chitarisiko chacho chakati sandara uye chakatsetseka (ona Mufananidzo 6), pasina zvikanganiso zvakaita sejecha, slag inclusions, cold shuts, nezvimwewo, ukobvu hwemadziro hwakaenzana, uye zviyero zvacho zvinosangana nezvinodiwa nemifananidzo.

(6) 20kg/cm2 hydraulic pressure test mushure mekugadzirisa haina kuratidza chero kubuda kwemvura.

6. Mhedziso

Zvichienderana nehunhu hwevharuvhu iyi yemabhururu, dambudziko rekusagadzikana uye nyore nyore kwejecha guru riri pakati uye kuchenesa jecha kwakaoma rinogadziriswa nekusimbisa pakugadzira hurongwa hwekuita, kugadzirwa nekugadzirisa jecha uye kushandiswa kwezvipfeko zvezirconium-based coatings. Kuisa maburi ekubuda kwemhepo kunodzivirira mukana wekuti pave nemaburi muzvipfeko. Kubva kuodzora kuchaja kwechoto uye system yekumhanya, foam ceramic filter screen uye ceramic ingate technology zvinoshandiswa kuona kuchena kwesimbi yakanyungudutswa. Mushure mekurapwa kakawanda kwekubaiwa, chimiro chemetallographic chezvipfeko uye zvakasiyana-siyana. Kushanda kwakakwana kwasvika pazvinodiwa nevatengi.

KubvaTianjin Tanggu Mvura-chisimbiso vharafu Co., Ltd. Vharuvhu yeshavishavi, vharuvhu yegedhi, Y-strainer, vharuvhu yekutarisa ndiro mbiri yewaferkugadzira.

Nguva yekutumira: Kubvumbi-29-2023